–CNC turning and CNC milling are the two most favored CNC machines. The two machining procedures are important, and, it’s Secure to convey, they may handle a lot of the work in a normal machine shop.

No interior conversion printer/serial port to USB software or extra conversion components is used with the MX.

I used to be as soon as in precisely the same boat as most as I was hunting for a CNC lathe which was compact, useful, and in good shape my finances. Eventually, machine quote right after estimate, I just felt additional discouraged and puzzled than in advance of I'd even begun my quest.

23. Use the optional Digital Probe to scan the profile and/or pockets of one's pleasurable/interest sort patterns to jot down your tool route system and machine out a reproduction of one's initial design To “surface area” scan an object, you may application the probe together the X or Y airplane.

CNC turning is well suited for executing a wide range of functions. We've got named many of them already but Enable’s just take a closer seem now to provide clarity for the capabilities of lathe machines.

CNC movements are depending on the X, Y and Z axes. The tool is positioned employing stepper or servo motors, which act within the movements based on the code acquired from the original 3D design of the portion you ought to produce – known as the G-code.

Its advanced technology, precision, and efficiency come up with a CNC lathe machine indispensable for a wide array of applications.

After that, We are going to just cover little CNC lathes normally. 1’s Which might be higher priced, but fit in a lesser footprint than their Significantly larger siblings.

A CNC lathe is an assembly of intricate components, Every single participating in an important function in its operation. Knowledge these components gives you a deeper insight into how these machines accomplish these high amounts of precision and efficiency. In this article’s a breakdown of The true secret parts:

You can push P to pause a program, press S to show Spindle On, G to run a plan, Place Bar to Stop, J to record your individual actions just one line at a time to create a plan in instruct method.

The flexibility in the CNC lathe machine causes it to be an ideal suit for industries including aerospace, automotive, health care, electronics, along with the military services, producing A variety of merchandise, from large airplane engine parts to small surgical devices.

Even the potent CAM packages might not generally get everything location-on, so examining the click here coded Recommendations is suggested.

The key difference lies from the movement of the workpiece, with CNC turning excelling in manufacturing cylindrical parts and CNC milling providing a broader choice of prospects for complex geometries.

3D Modeling Software: Employed for making complex 3D models that can be translated into machining functions. Rhino and Blender are suited for additional artistic or intricate layouts.

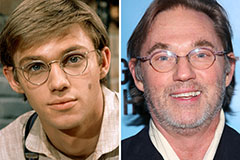

Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!